Shining 3D scanner and Siemens NX 12 case study

Extract geomaterial dimension from the physical part by using Shining 3D scanner and Siemens NX 12 CAD software.

Quality control, or QC for short, is a process by which entities review the quality of all factors involved in the production. ISO 9000 defines quality control as "A part of quality management focused on fulfilling quality requirements".

This Inspection is a major component of quality control, where a physical product is examined visually (or the end results of service are analyzed). Product inspectors will be provided with lists and descriptions of unacceptable product defects such as dimensions not within tolerance.

Challenge:

Most of the manufacturing companies will go through this process. But most of them have difficulty to measure the part accurately due to many reasons. Such as part is too big or too small, uneven surface, or hard to measure geometry (cone, surface angle, surface profile, and etc). Although a proper measurement tool (contact measurement tool such as caliper, angle ruler) is provided, the accuracy of the measurement also is part of the issue.

Solutions from DTS

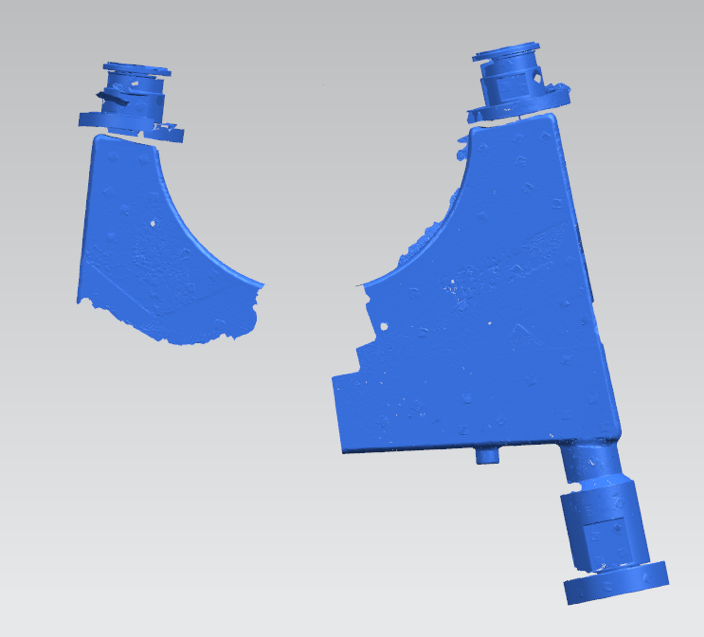

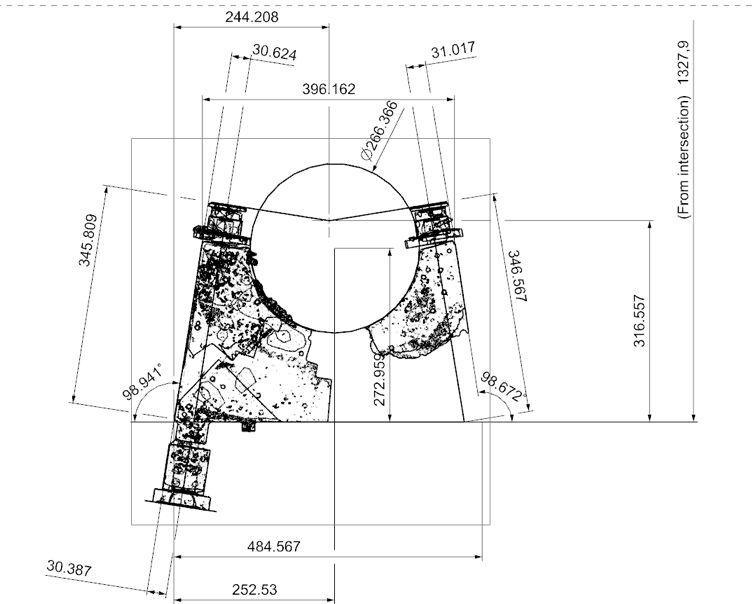

One of the case here where a company approach us and need our help to extract some dimension measurement from their part (as shown below).

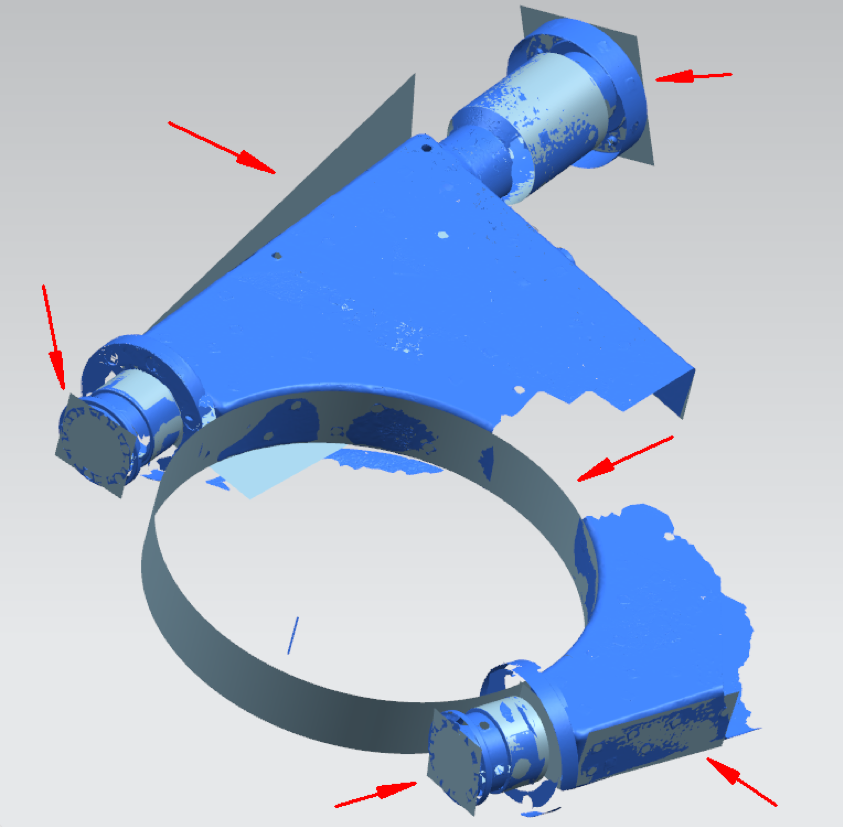

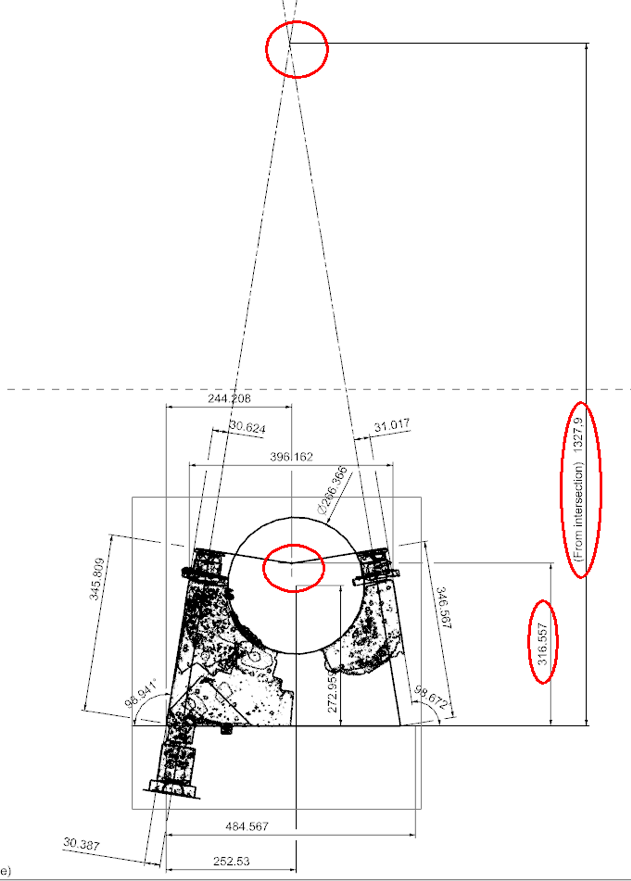

the most challenging part is to get the centerline of both cylinders and get the intersection point of both lines, which nearly impossible for manual measurement. So we propose them to use a shining 3D scanner + Siemens NX 12 to get the dimension they needed.

- First, we get the part scanned by using shining 3D Einscan-pro scanner. The customer only require dimension from specifying portion, so we just scan the part partially as shown below:

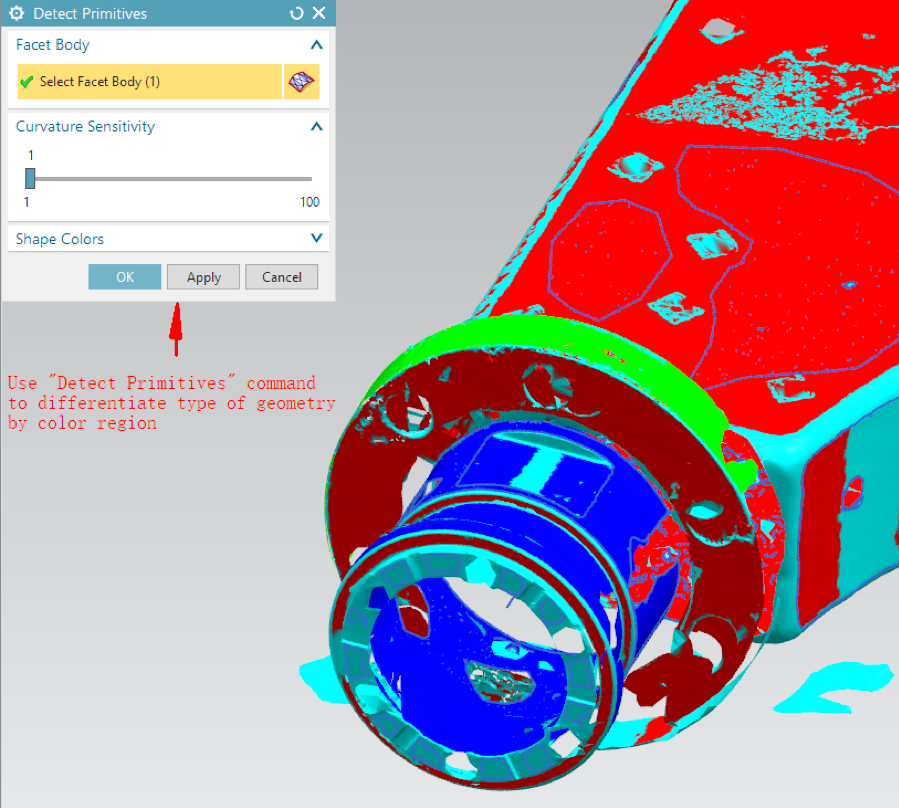

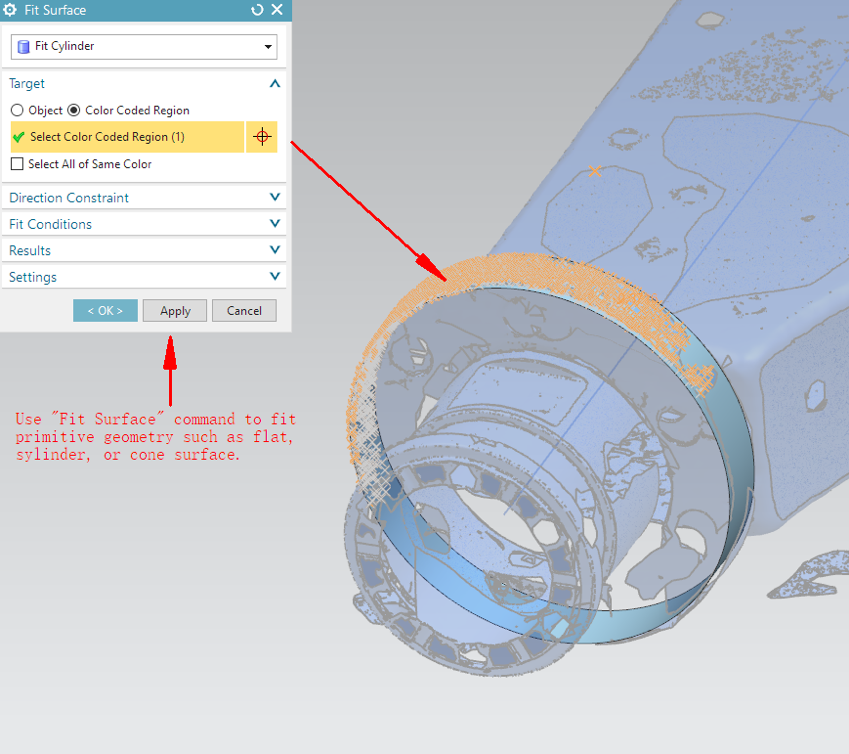

2. After scan, we get the scan data into NX 12 to do the alignment + fit primitive geometry (such as flat, circle, or cone surface) to scan data by using Reverse Engineering tool in NX:

3. Bring the 3D into drawing, create dimension base on the geometry we created. Thus, from the geometry, we can get the intersection point between 2 cylinder lines very easily by extending it.

Outcome:

As a result, the overall scan to result time is about 2 hours and dimension can be measure accurately without any problem. So, this proves the measurement method by using scanner + Siemens NX 12 able to extract out hard to measure dimensions from the physical part in a short period of time accurately.

Found above case study similar to your challenges?

We at DTS can help! Speak to our Representative.

With more than 15 years of experience in PLM solution, our consultants and engineers are equipped with great skills and knowledge and ready to help.