ZW3D for Mold Design

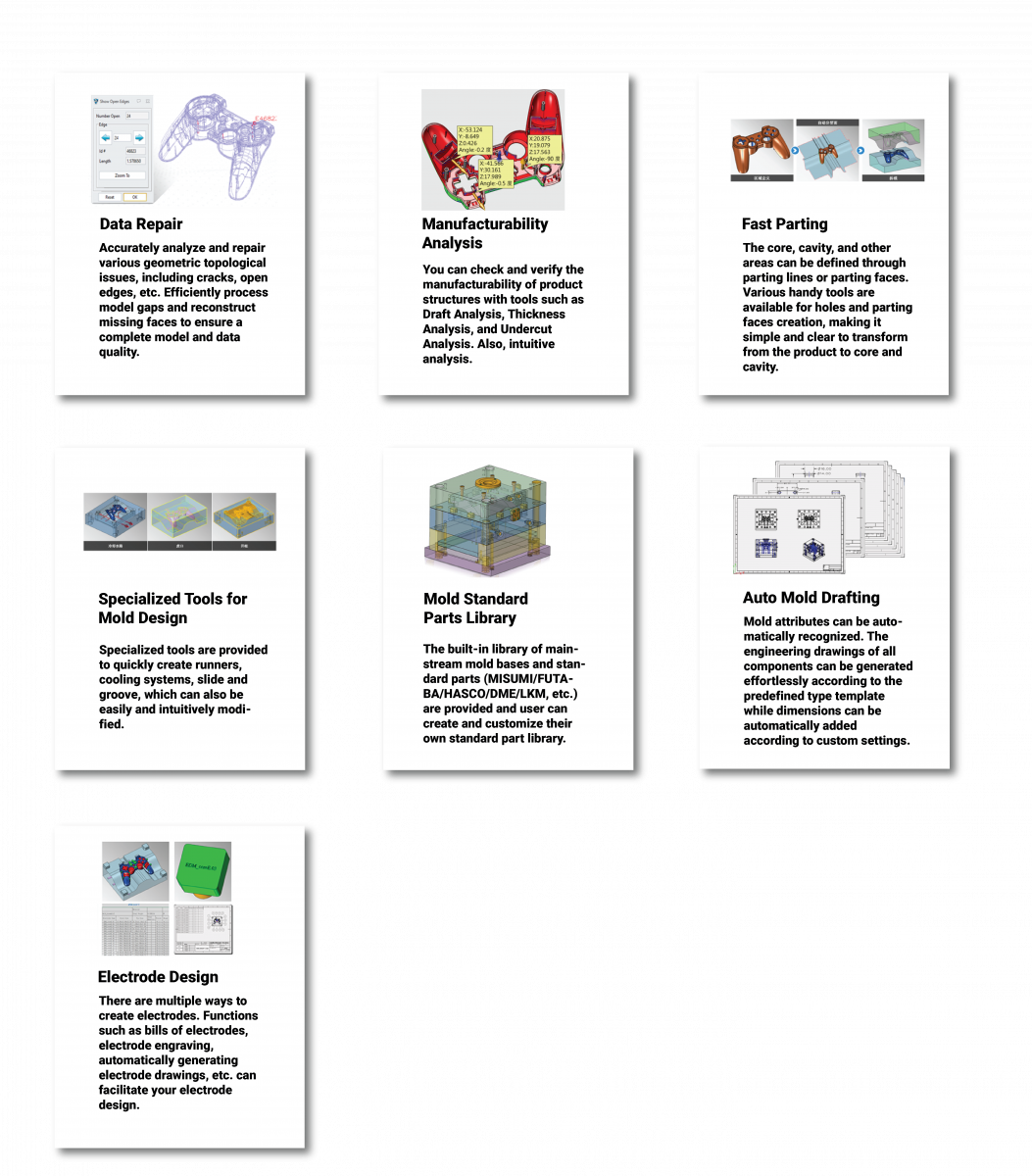

The ZW3D Mold design solution covers your needs throughout the whole-process of mold design, providing high-quality data import, smart model healing, unique non-solid mold parting, extendable mold base and standard parts, practical electrode design, 2D document and etc.

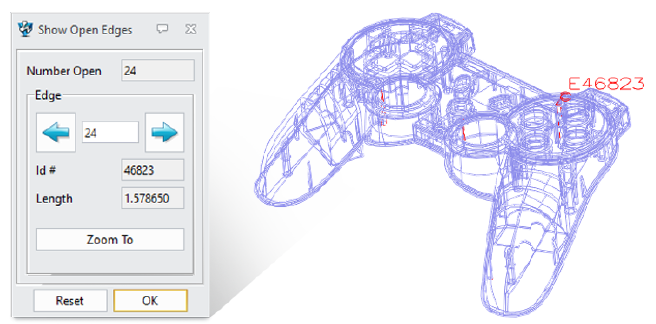

Powerful Repairing for Guaranteed Data Quality

Repeated surfaces and open edges, among other geometric topological states, can be precisely analysed and restored.

A complete solid model is ready to ensure data accuracy, with geometric holes efficiently filled and missing surfaces reconstructed.

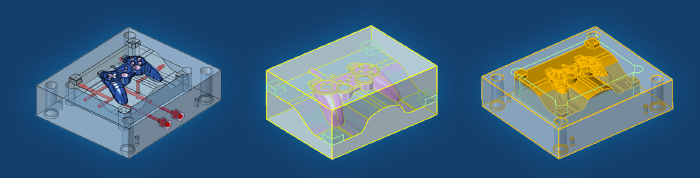

Fast Core-Cavity Parting to Accelerate Mold Design

• When it comes to model healing, parts can be parted directly utilising parting lines or parting faces that can be generated automatically, saving you time.

• Multi-cavity design is enabled to accommodate a variety of product design objectives.

Abundant Library of Mold Bases & Components with Different Standards

The built-in library of mold bases and standard parts can be customized to suit the needs of various countries and businesses.

Specialized Tools for Detailed Mold Design

Specialized tools are offered to easily and intuitively modify runners, cooling systems, slides, and gates.

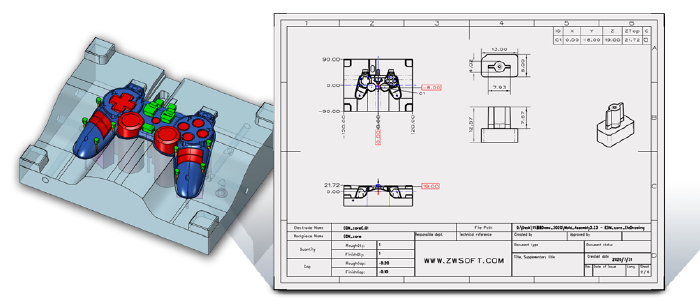

Efficient Solutions for Complex Electrode Design

• Electrode extract tools allow you to easily deal with complex electrodes.

• Electrodes and 2D sheets can be correctly created in batches to save your time.

Features

Need help with ZW3D for Mold Design?

DTS is the authorized partner of ZWSOFT in Singapore & Malaysia.

Speak to our representative!

With more than 15 years of experience in PLM solution, our consultants and engineers are equipped with great skills and knowledge and ready to help.

Case Studies of ZW3D for Mold Design

- Alfatech Technical Design Our Customers' Voices

- M-Fischer Tech Our Customers' Voices