Reverse Engineering / 3D Scanning / Inspection Services in Malaysia, Singapore

Need to perform an updated design from existing product?

Rebuilding Class A surfaces for automotive components, or creating implants or prosthetics from 3D anatomical scans?

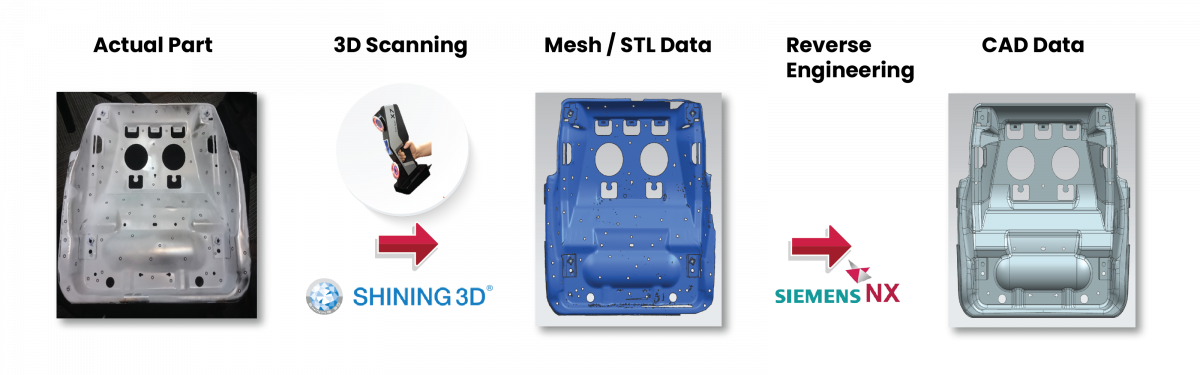

Reverse engineering service is a longstanding practice in product development of transforming the physical product into 3D digital parametric CAD geometry.

For the scanning operation, the handheld high definition scanner, Shining 3D Freescan x5 scanner (but not limited to) is used for most of the scanning operation. . Freescan x5 can scan up to 550,000 points per second, and accuracy up to 50microns. It also has more flexibility to scan medium to large size of object easily thanks to it technology.

As a result of the scanning operation, a thorough point cloud data of the physical product is obtained. The data is meshed within the scanner proprietary software, before sending out to the best-in-class Siemens NX software for reverse engineering operation.

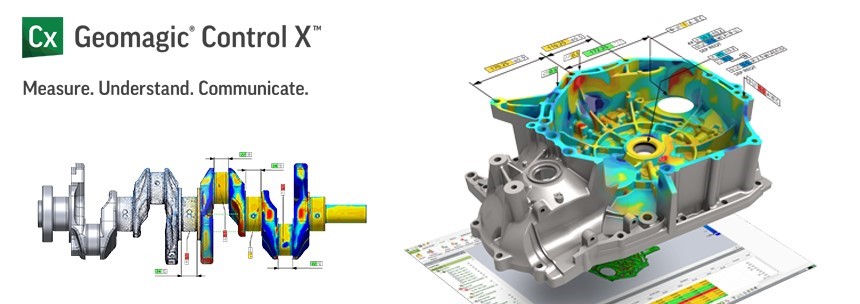

In situations where firms may want to probe for the accuracy of their finished manufactured product, 3D inspection service is available to compare the geometry variants between the 3D scanned data and the original 3D cad data, for quality assurance purposes.

Check out the video to discover the scanning process!

Speak To DTS Representative

With more than 15 years of experience in PLM solution, our consultants and engineers are equipped with great skills and knowledge and ready to help.

Case Studies related to Reverse Engineering / 3D Scanning / Inspection Services in Malaysia, Singapore

- Shining 3D scanner and Siemens NX 12 case study Actual Industrial Case Study

- Case Study: 3D Scanning of Castings for Dimensional Inspection Actual Industrial Case Study

- Stormtrooper helmet Scanned by the EinScan Pro 2X Plus Actual Industrial Case Study