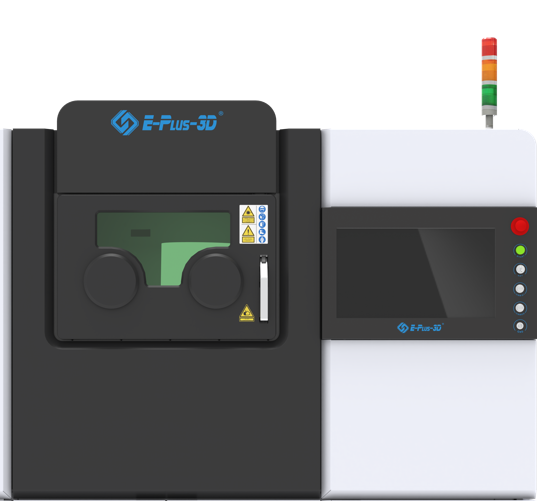

EP-M260 Metal 3D Printer

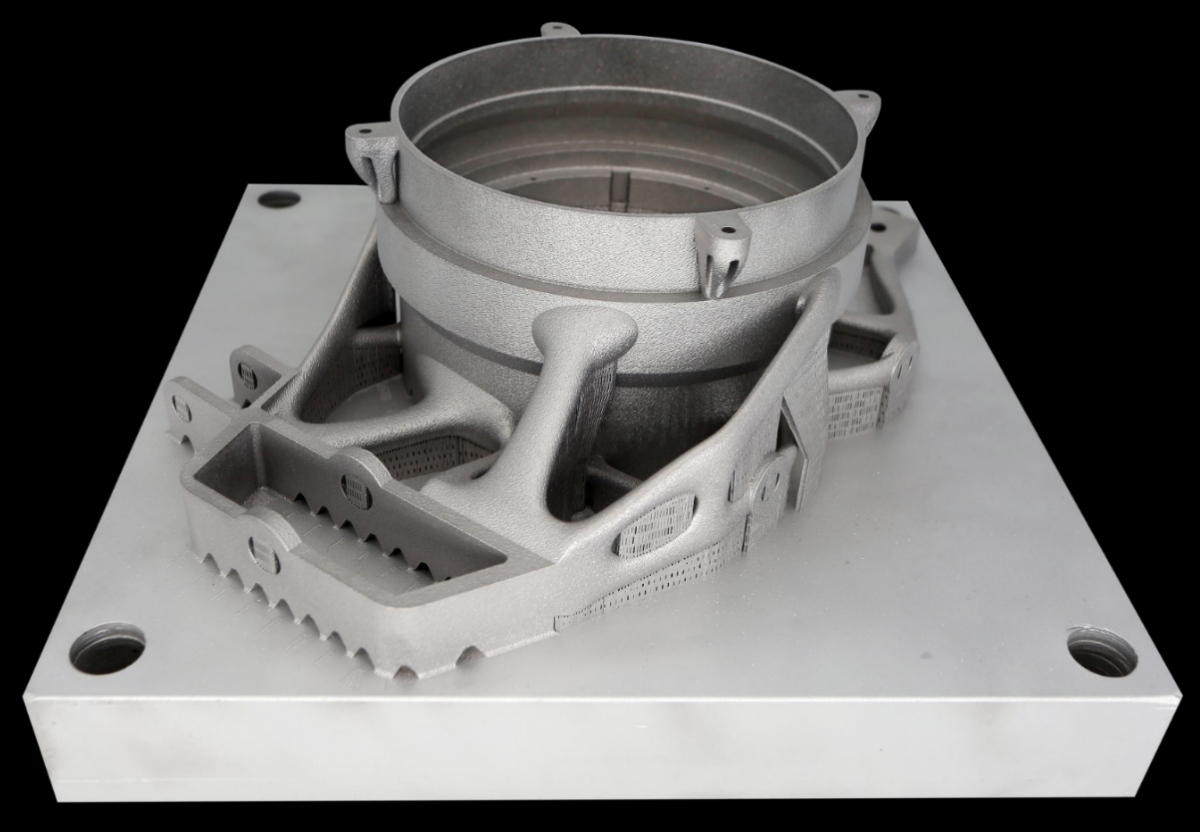

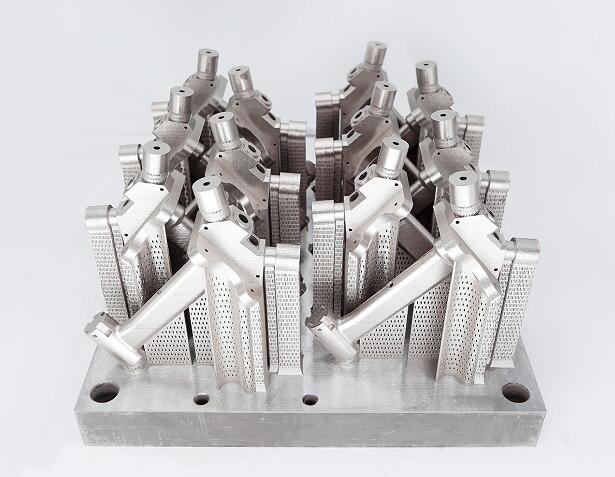

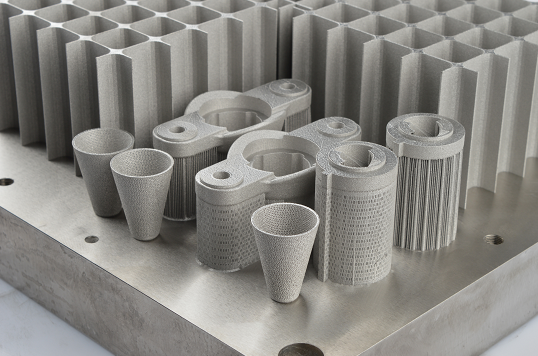

The EP-M260 is an industrial grade metal 3D printer that uses advanced metal powder bed fusion (MPBF) technology. It is capable of easily and quickly converting CAD data into high-performance, complex structure metal parts. The 3D printer is an ideal choice for medium sized parts and small batch production.

EP-M260 Metal 3D Printer Features

Consistent Performance

-

Innovative gas flow management and optimized filter system ensure a stable building environment

-

Outstanding sealing capability optimizes oxygen content

-

Precise laser beam quality control

High Productivity

-

Dual-Laser system equipped with build volume of 266x266x390mm³

-

Non-stop operation during filter change

-

Optimized recoating strategy shortens coating time

Reliable and Easy Operation

-

Convenient powder recycling systems and glove box structure minimize powder contact

-

Intelligent software ensures less human intervention

-

Real-time monitoring of the production environment and building process

Low Operation Cost

-

Quantitative powder feeding and coating ensure less powder waste

-

Advanced filtration system significant increases filter lifetime

-

Low inert gas consumption during purging and operation

Glove-box Type Access Door

-

Intelligent electronic lock with no need of manual operation

-

Double locking from mechanical lock to improve safety

-

Alarming when the access door is open abnormally, to ensure the safety of use

-

Two-glove structure of the access door makes it possible to operate without opening the door

-

Tension seal with good sealing performance, can be controlled both automatically and manually

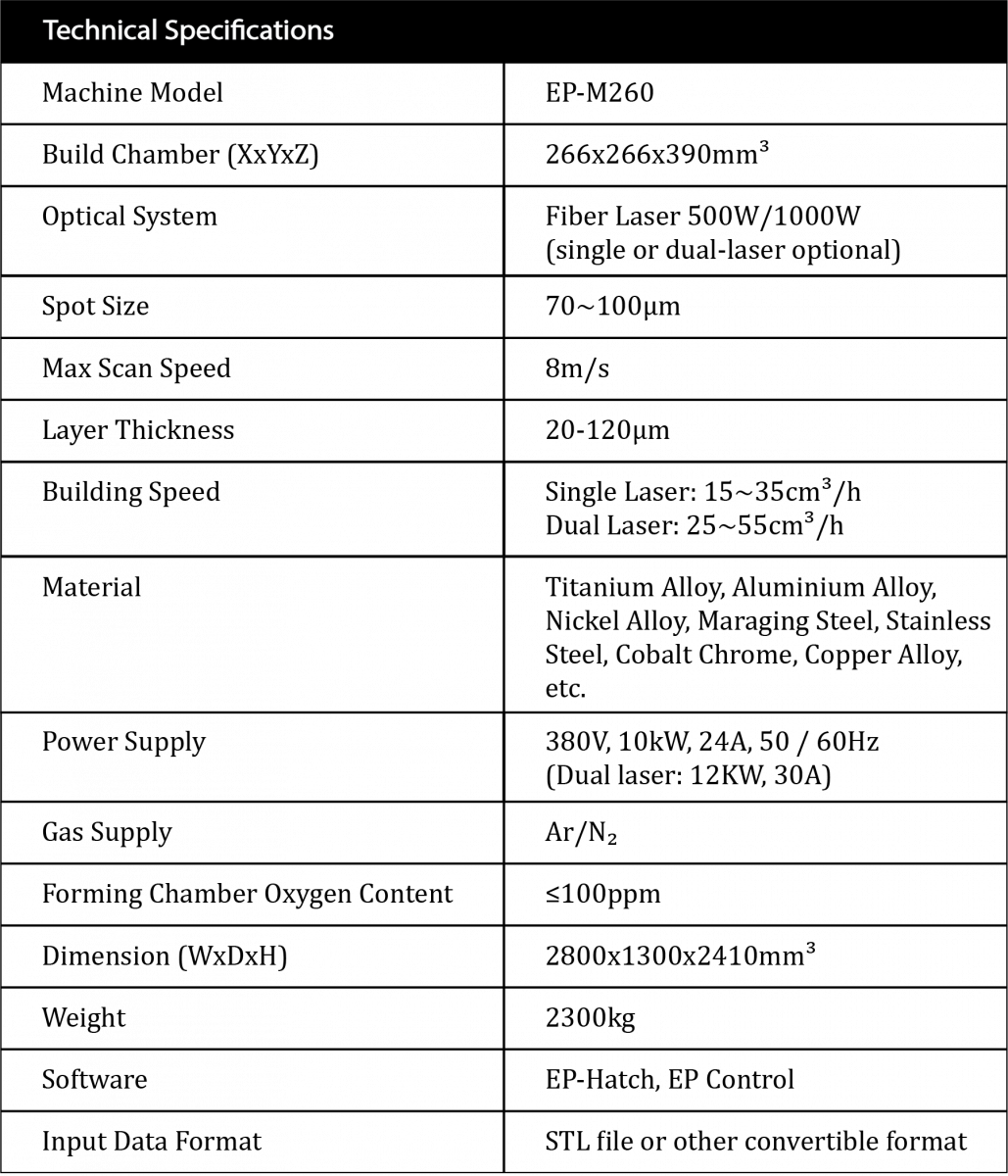

Technical Specifications

Need help with EP-M260 Metal 3D Printer?

DTS is the authorized partner of Eplus3D in Singapore & Malaysia.

Speak to our representative!

With more than 15 years of experience in PLM solution, our consultants and engineers are equipped with great skills and knowledge and ready to help.