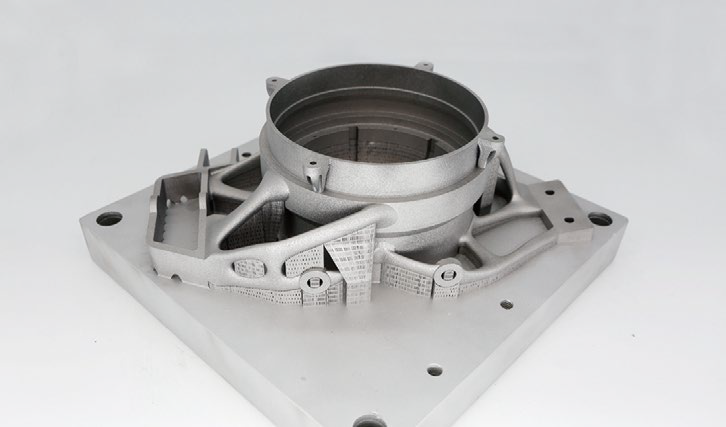

EP-M250Pro Metal 3D Printer

The EP-M250Pro is a dual-laser equipped metal 3D printer that uses advanced MPBF™(Metal Powder Bed Fusion) technology for metal additive manufacturing with high productivity and high consistency. Machine building chamber size is 262x262x370mm. The Innovative module design not only ensures the stability and safety of the machine operation, but also help our customer with easy maintenance and transportation.

EP-M250Pro Metal 3D Printer Features

Consistent Performance

-

Innovative gas flow management and optimized filter system ensures a stable building environment.

-

Outstanding sealing capability minimizes oxygen content.

-

Precise laser beam quality control.

Low Operation Cost

-

Quantitative powder feeding and coating ensures less powder wastage.

-

Advanced filtration system significantly increases filter lifetime.

-

Low inert gas consumption during purging and operation.

High Productivity

-

Dual-Laser system equipped with build volume of 262x262x350mm.

-

Non-stop operation during filter change.

-

Optimized recoating strategy shortens coating time.

Reliable and Easy Operation

-

Convenient powder recycling systems and glove box minimizes powder contact.

-

Intelligent software ensures less human intervention.

-

Real-time monitoring of the production environment and building process.

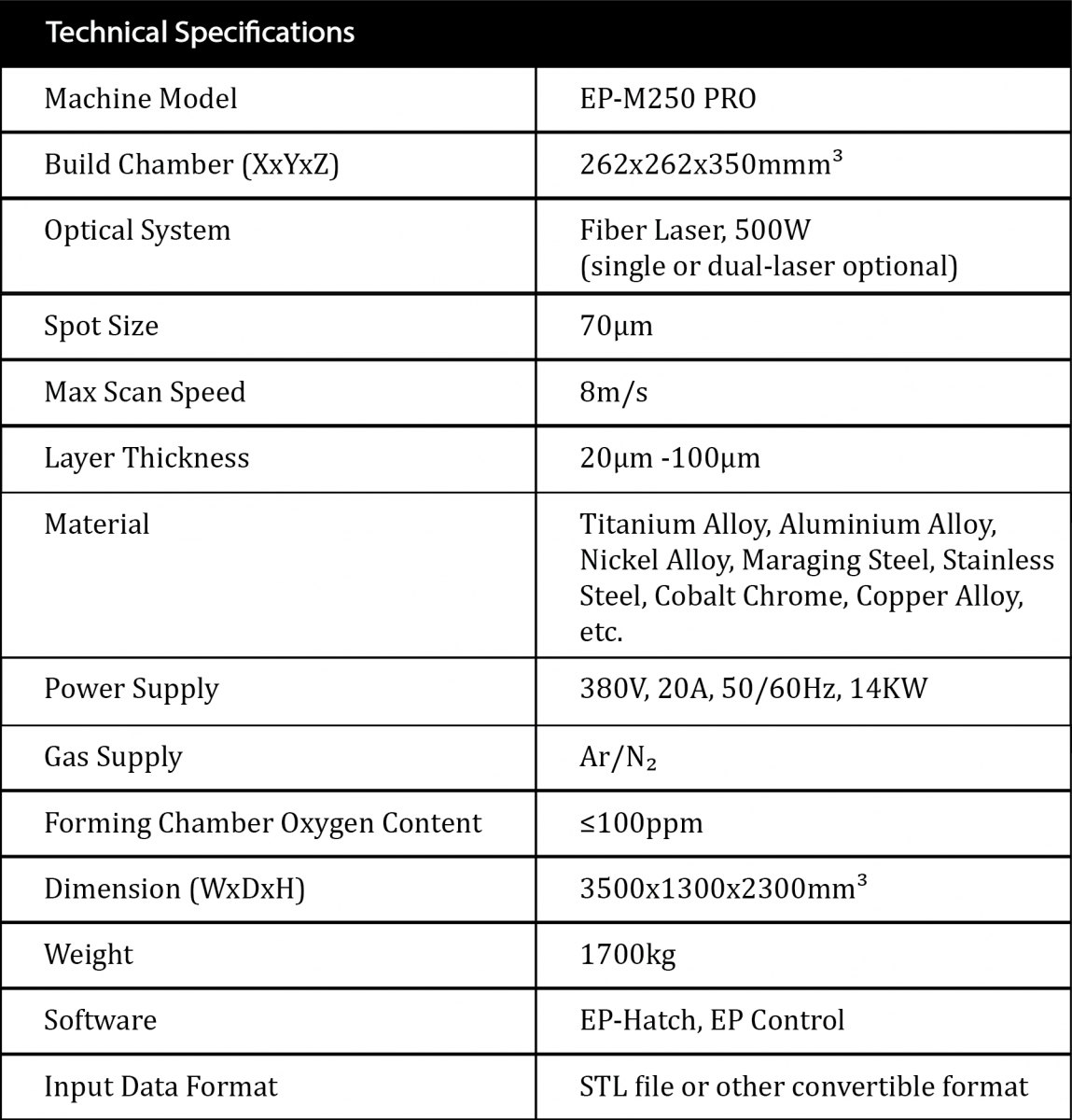

Technical Specifications

Need help with EP-M250Pro Metal 3D Printer?

DTS is the authorized partner of Eplus3D in Singapore & Malaysia.

Speak to our representative!

With more than 15 years of experience in PLM solution, our consultants and engineers are equipped with great skills and knowledge and ready to help.