EP-C7250 Wax/Sand SLS 3D Printer

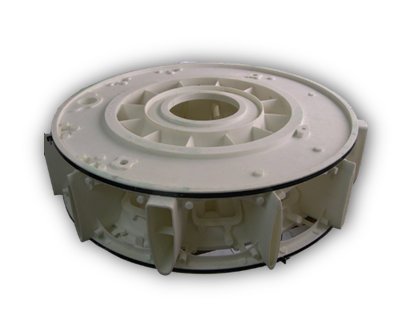

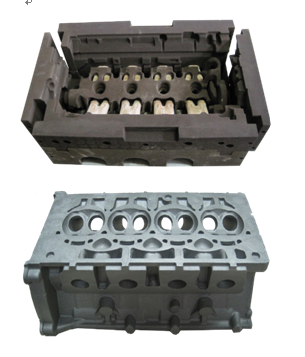

EP-C7250 is able to use resin sand to print sand molds. Together with traditional casting technology, the molds is possible to cast engine blocks, cylinder heads, turbines, impellers, and other components with complex structures in a very short time. The building chamber size is 720x720x500mm.

EP-C7250 Wax/Sand SLS 3D Printer Features

Material

-

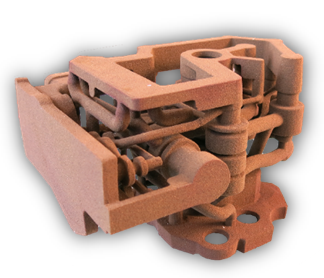

Resin Sand based, cost-effective pattern casting material, which is compatible with most standard casting processes. It is suitable for prototype metal castings and can be produced in low to medium output without the use of tools.

Wide Application

-

EP-C7250 SLS 3D printer offers huge build size and can rapidly cast the parts with complex structures, like engine cylinder block, cylinder head, turbine, impeller, etc.

High Cost-Effective and Fast Prototypes

-

EP-C7250 casting printer greatly reduces the R&D and trial-producing time for casting parts with fast sand and wax mold printed directly.

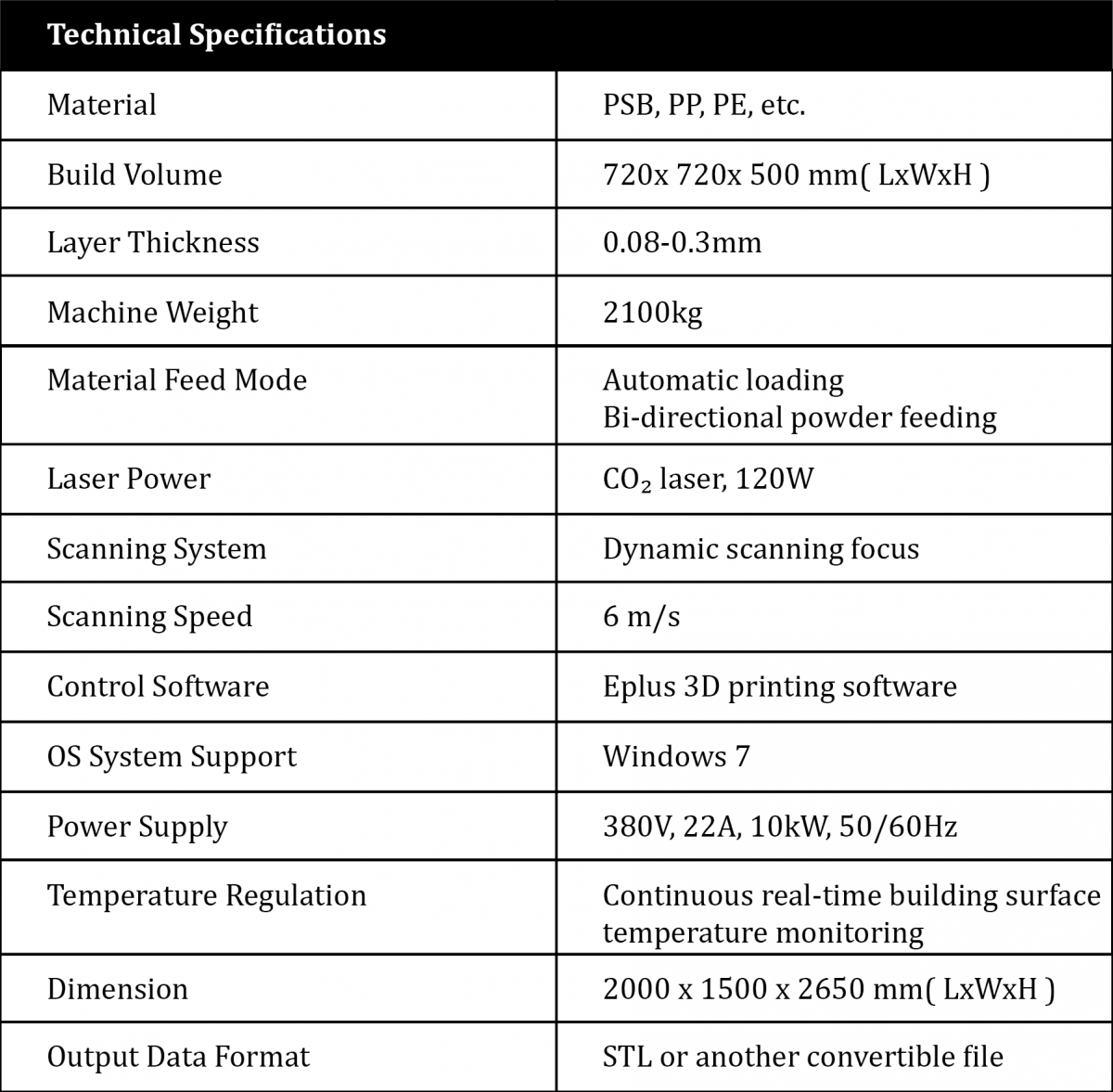

Technical Specifications

Need help with EP-C7250 Wax/Sand SLS 3D Printer?

DTS is the authorized partner of Eplus3D in Singapore & Malaysia.

Speak to our representative!

With more than 15 years of experience in PLM solution, our consultants and engineers are equipped with great skills and knowledge and ready to help.